SUMCO WINDER

Lenze i550 & g500 winder drive – Cost effective winder drive replaces DC drive and expands controllable range of speeds

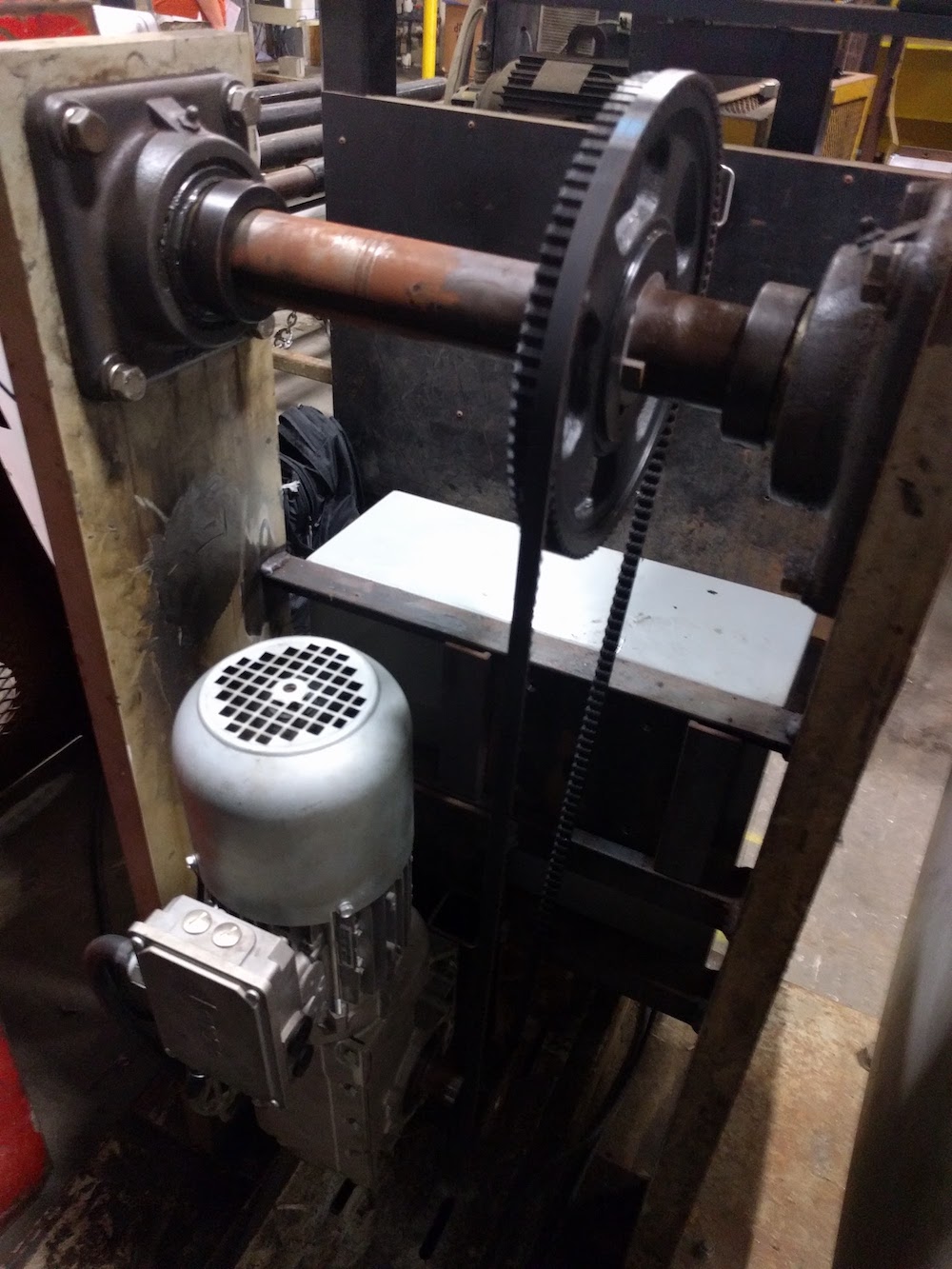

Machine

Winds up metal after processing into a coil. Operators control tension using a potentiometer and operate mainly by feel.

Problem

Customer had several winders with DC drives and motors. The same model of current DC drives used are getting scarce. Maintenance department setup each drive using a torque wrench and trim pots. Customer tried changing to another model or brand of DC drive but could not get the winders to perform.

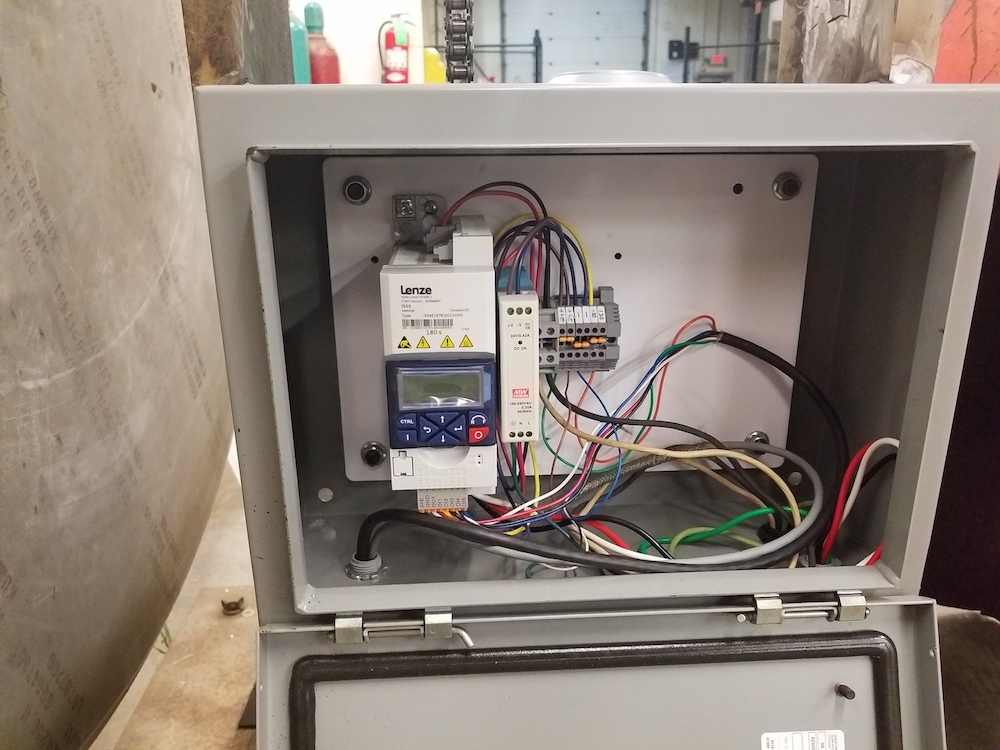

Our Solution

Lenze i550 drive in Asynchronous Servo Mode (ASM) and Torque mode. Since the motor and drive are both manufactured by Lenze there was minimal tuning required.

In testing the winder on a rework station winder was able to operate from 1.8 to 46 FPM. Torque is consistent when the line was stopped and restarted. Operator uses selector switch to turn on and pick direction and adjusts torque (tension) using a potentiometer.

Application Gallery