AUTOMATED COATER GAP ADJUSTMENT

Machine

Roll coating machine used to apply various coatings to sheet or web goods

Opportunity

Customer wanted to automate the gap adjustment on a coating machine and replace a handwheel and mechanical position with a servo drive.

Our Solution

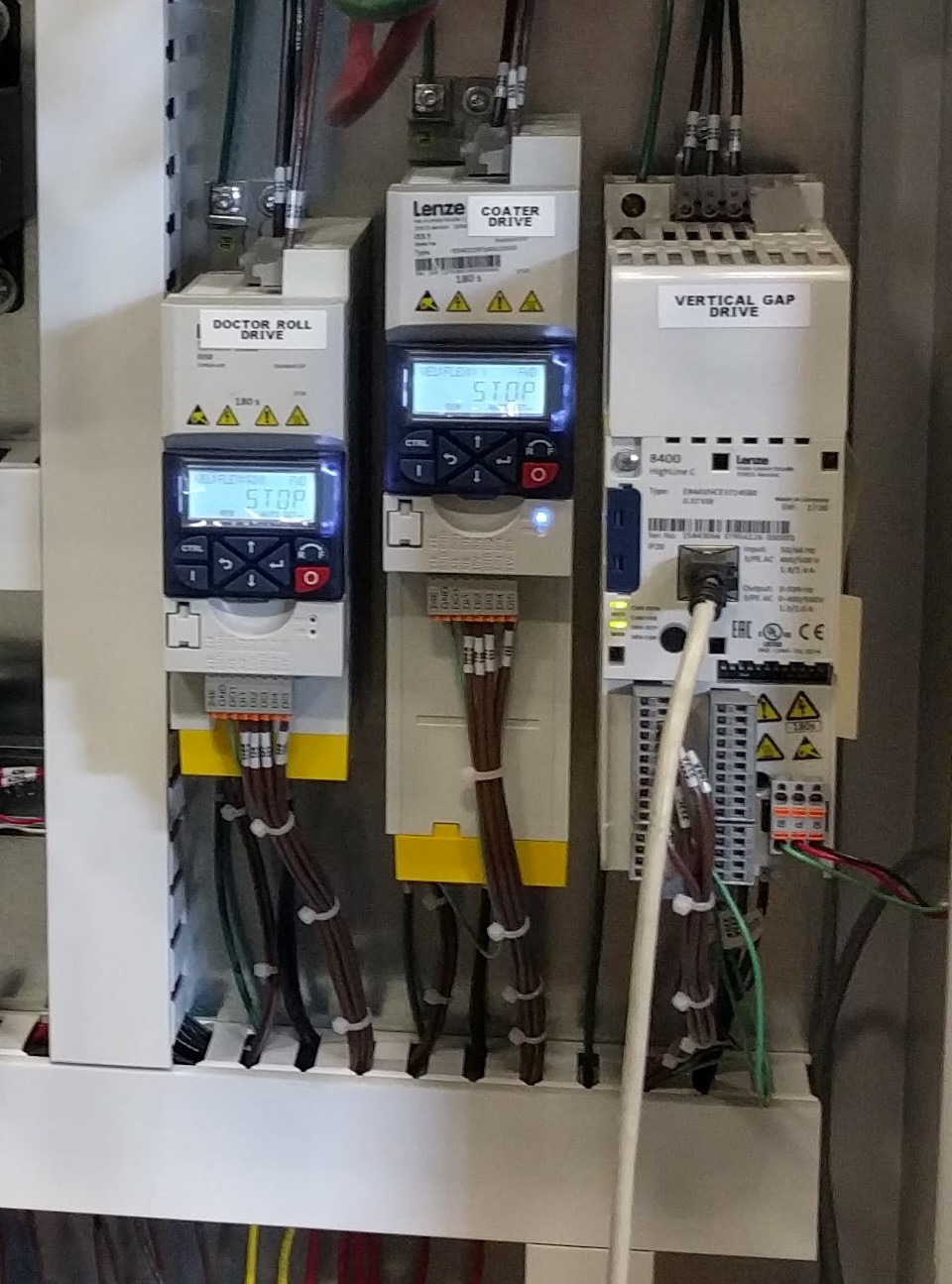

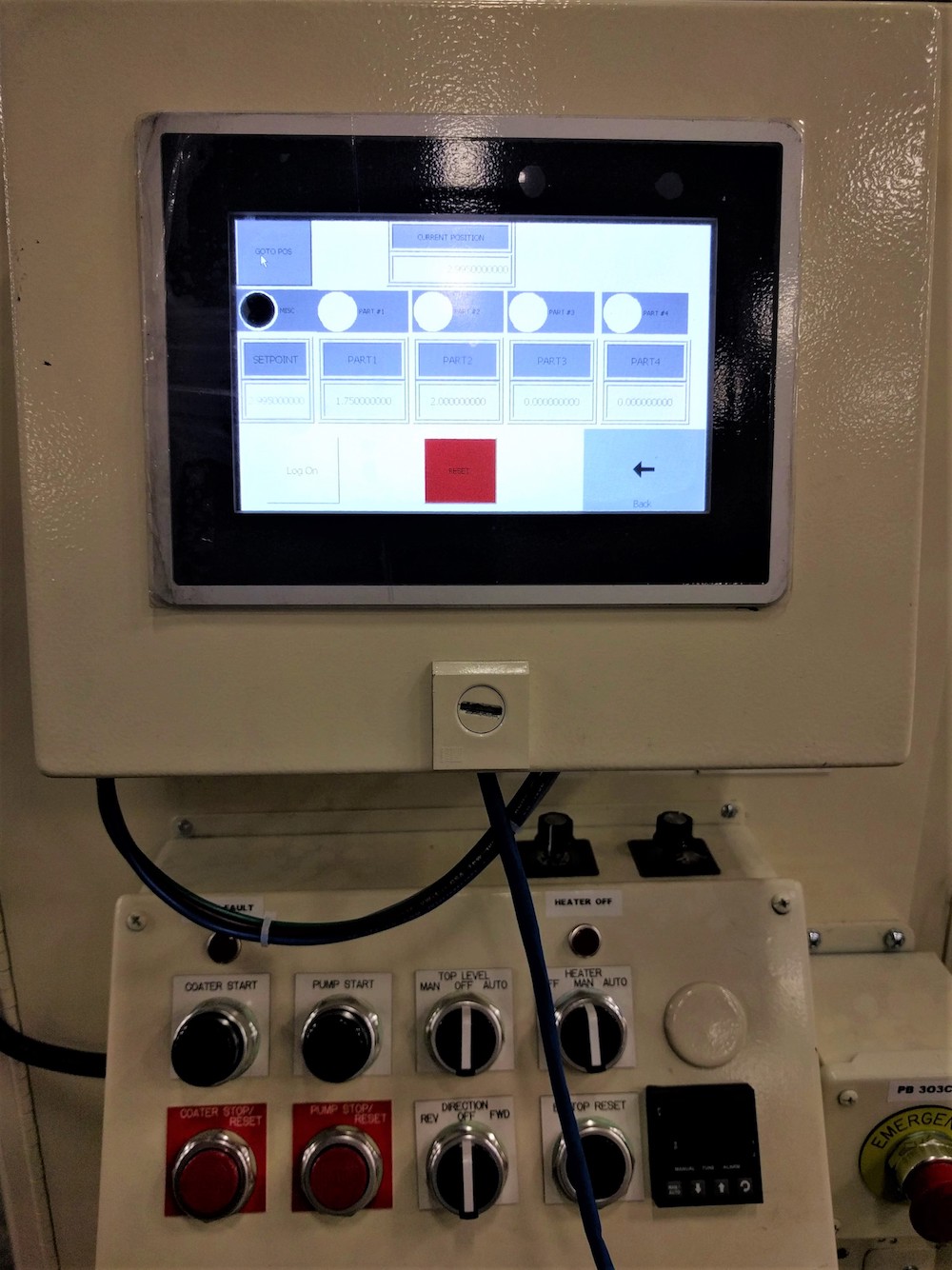

Lenze 8400 Highline drives position accurately with a standard induction motor and encoder. The drive is operated in ASM (Asynchronous Servo Mode) and while it can’t move as dynamically as a permanent magnet servo motor it positions as accurately as a full servo system. Perfect for this application. This reduces the cost of the drive, motor, encoder and cables. The p300 touchscreen and 8400 have CANbus so no additional communication modules are needed.

From the home screen on the p300 the operator selects Homing, Positioning, Jog or Cleanup (full open) mode. The touchscreen sends the inputs to the 8400 Highline via CANbus. The 8400 handles the logic to allow correct operation and moves the coating roll into the desired position. Lenze’s 128 ppr incremental encoder is an inexpensive option that can be added to a g500 gearmotor. Since Lenze makes both the motor and the drive the motor parameters are automatically be loaded into the drive when the motor is selected from a list in the software. This minimizes the time spent tuning the entire system.

Note: in the picture of the three drives side by side the Lenze 8400 is on the right. The other two drives are Lenze i550 drives

Application Gallery